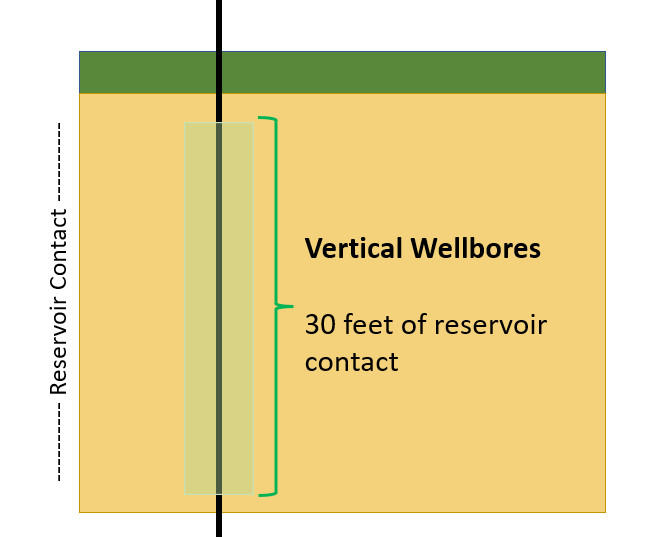

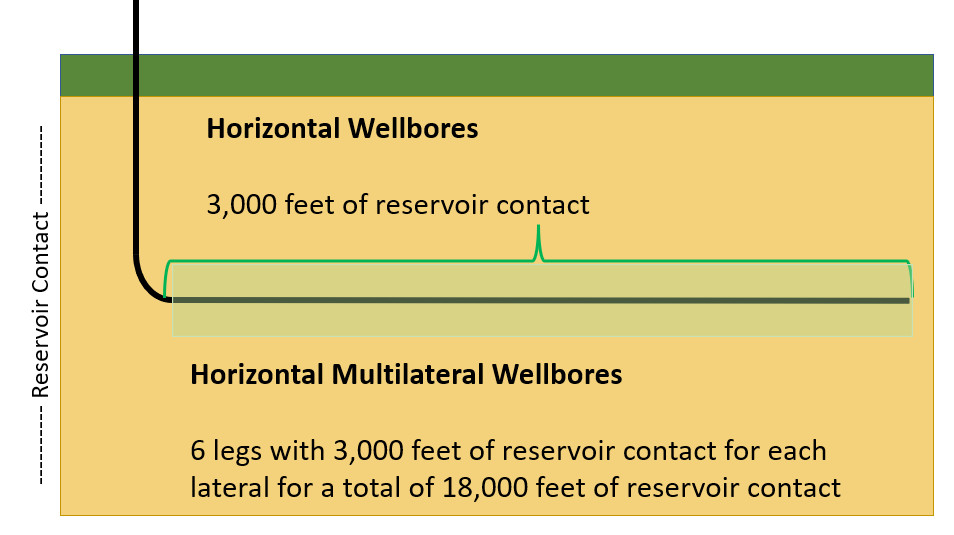

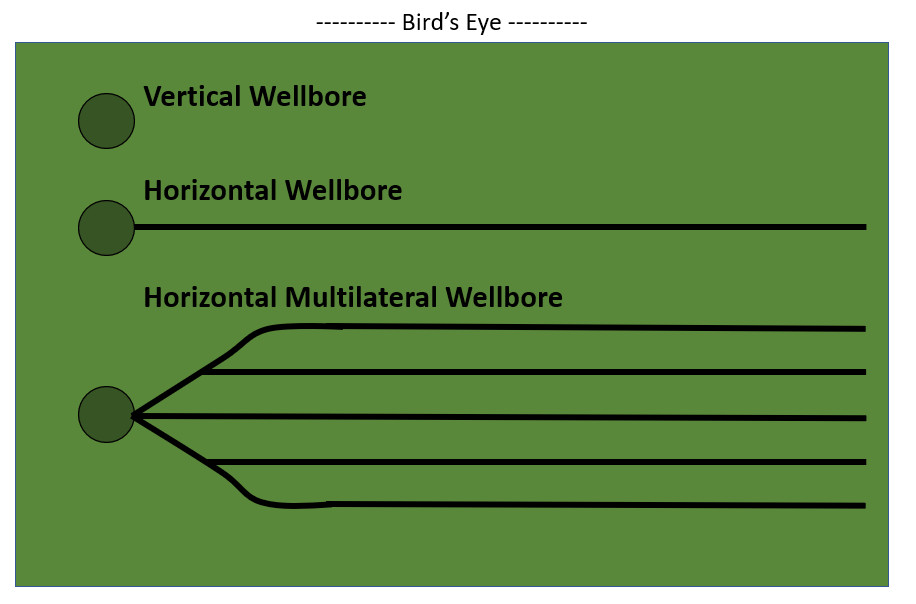

Oil well productivity is a function of surface area. The greater the surface area, the greater the instantaneous production potential (holding the reservoir characteristics constant).

Over the past 30 years operators have learned how to use different technologies depending on the reservoir characteristics of their targeted oil-bearing rock.